Floor Waterproof Wax

Description

This product is a floor protective material with suitable consistency, freezing point, good chemical stability, thermal stability and water resistance.Its main functions have the following five aspects:

1. Waterproof: Through the surface treatment of the wooden floor enterprise mouth, the penetration of the pores on the surface of the wooden floor is blocked and the conjunctiva is covered, so that moisture and dust cannot invade the floor substrate, thereby forming a protective barrier and achieving a waterproof effect.

2. Glue-free: the double-locking design of the new floor and the protection of the waterproof wax film on the entrance of the enterprise make the floor completely free of patchwork glue when paving.

3. Environmental protection: The protective wax material is green, environmentally friendly and pollution-free. At the same time, the wax forms a continuous, dense and flexible sealing layer at the entrance of the floor to seal the release of formaldehyde.

4. Extend the life of the floor: protective wax coating is applied to the opening of the floor to solve the uneven height and force of the floor caused by water absorption and expansion and thickening of the bumps at the joints of the floor. The raised parts are whitened first and damaged first, reducing the moisture absorption and expansion rate, improving dimensional stability, and extending the service life of the floor.

5. Anti-aging: The sealing and anti-aging characteristics enable the wax film to effectively prevent the oxidation reaction between the surface of the floor enterprise, especially the composition of the adhesive in the substrate, and the air, which slows down the oxidation and aging of the floor enterprise, and increases the life of the floor.

6. Lubrication: It can effectively reduce the coefficient of friction of the tenon groove and tongue, and reduce the noise caused by the surface contact and relative movement of the wooden floor during the use of the wooden floor.

Additional Information

Recommendations for use

1. This product should be stored in a ventilated and dry place with a temperature of less than 30℃.Granular products will have slight agglomeration in summer, which will not affect the use of the product.

2. During use, the temperature of the wax box is recommended to be controlled between 80℃-110℃.Pay attention to different seasons, and pay attention to adjusting the temperature of the wax box. The temperature in summer (June-September) should be 10-15℃ higher than the temperature in other seasons.

3. Recommended model for use:

Floor wax DT-3 has a high oil content, high content of small molecular compounds, and strong permeability. It can penetrate into the pores on the surface of wooden floors, and has excellent waterproof and formaldehyde sealing function.

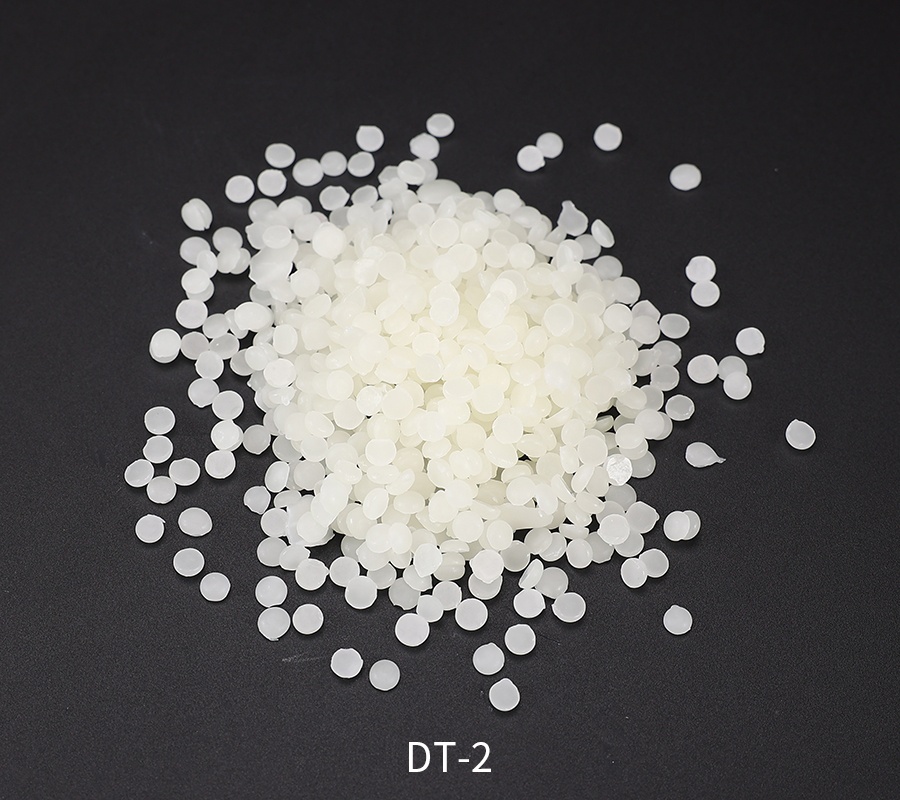

Floor wax DT-2 has a high melting point, low oil content, and appropriate viscosity. It can form a continuous, dense, and extremely flexible conjunctiva at the mouth of the wooden floor enterprise. It has good lubrication and fixation effects, and reduces the friction between the tenon groove and the tongue.

During use, it is recommended to choose the appropriate floor wax according to the type of wooden floor, the sealing wax process, and the needs of practical applications.The two floor waxes can also be deployed in any proportion according to demand, so as to be both effective waterproof, lubricating and fixing, effectively control the waterproof expansion rate and dimensional stability of wooden floors, and ensure the long-term stability of wooden floors.

4. Recommended usage

During the wax sealing process, it should be ensured that the wax spraying is complete, continuous, and the amount of spraying is stable.The recommended amount of wax sealing is between 1-1.5g/m, and the specific amount used is subject to the actual process adjustment.

Wax seal quantity calculation formula:

M--Amount of sealing wax, g/m

Me-The weight of the floor after spraying, g

Ma-The initial weight of the floor, g

L-The length of the floor, m

B-The width of the floor, m

Product Application

This product can be used for high- and mid-range wooden floors and laminate flooring, as well as other wood products, as a waterproof agent to prevent the invasion of water vapor and seal the release of formaldehyde.